Duplex 2205 vs Super Duplex: Key Differences, Uses & Benefits

Aug 29, 2025

When it comes to stainless steel alloys, Duplex 2205 and Super Duplex are two terms often thrown around, especially in industries requiring high strength and corrosion resistance. Understanding the key differences between these materials is crucial for selecting the right one for your project.

What is Duplex 2205?

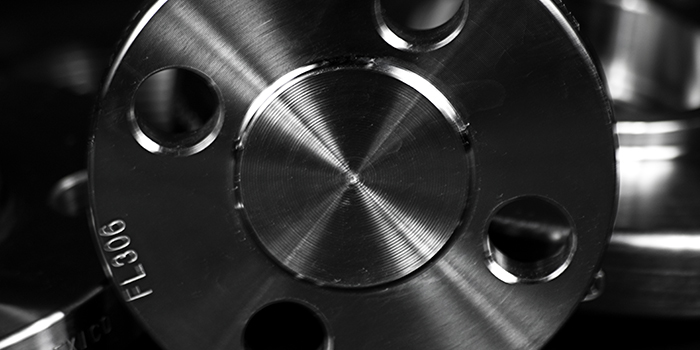

Duplex 2205 stainless steel is a nitrogen-enhanced duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels. With its high chromium and molybdenum content, Duplex 2205 offers improved resistance to pitting and crevice corrosion, making it an ideal choice for harsh environments.

For more detailed information about its composition and applications, visit our comprehensive guide on Duplex 2205 stainless steel.

Understanding Super Duplex

Super Duplex stainless steels are a higher alloyed category of duplex stainless steels, offering even greater strength and corrosion resistance. These steels are designed for demanding applications where Duplex 2205 might not suffice. Super Duplex features increased chromium, molybdenum, and nitrogen content, which enhances its performance in more extreme environments.

Key Differences Between Duplex 2205 and Super Duplex

1. Chemical Composition

While both are duplex steels, Super Duplex contains higher levels of chromium and molybdenum, which contribute to its superior corrosion resistance.

2. Mechanical Properties

Super Duplex grades typically offer higher tensile and yield strength compared to Duplex 2205, making them suitable for heavier loads and extreme conditions.

3. Corrosion Resistance

Super Duplex exhibits better resistance to stress corrosion cracking, pitting, and crevice corrosion, particularly in chloride-rich environments.

Common Uses of Duplex 2205 and Super Duplex

Duplex 2205 is widely used in applications such as oil and gas exploration, chemical processing, and marine environments. Its balanced properties make it a versatile choice. On the other hand, Super Duplex is preferred for more severe conditions such as deep-sea operations, offshore platforms, and chemical tankers, where enhanced corrosion resistance and strength are paramount.

Benefits of Using Duplex and Super Duplex

Both Duplex 2205 and Super Duplex provide a combination of properties that make them invaluable in specific industries. They offer excellent resistance to corrosion, high strength, and cost-effectiveness compared to some other stainless steel alloys.

For a deeper dive into stainless steel options, explore our range of high-quality materials tailored to meet diverse industrial needs.

Conclusion

Choosing between Duplex 2205 and Super Duplex depends on the specific requirements of your application. While Duplex 2205 offers a great mix of strength and corrosion resistance, Super Duplex is the go-to for more demanding environments. Understanding these differences will help you make an informed decision, ensuring longevity and performance in your applications.

Ready to choose the right stainless steel for your project? Explore our comprehensive selection at James Duva Inc. and enhance your industrial processes today!

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.