A Comprehensive Guide to Duplex 2205 Properties

Jan 26, 2026

Why Duplex 2205 Stainless Steel Matters for Industrial Applications

Duplex 2205 is a high-performance stainless steel alloy that combines the best properties of two different steel structures – austenitic and ferritic – into one material. This unique dual-phase composition delivers approximately twice the strength of standard stainless steels like 316L, along with superior resistance to corrosion in chloride-rich environments.

Quick Facts About Duplex 2205:

- Type: Duplex (austenitic-ferritic) stainless steel

- Key Composition: 22% chromium, 3% molybdenum, 5-6% nickel, 0.14-0.20% nitrogen

- Yield Strength: 65 ksi minimum (double that of 316L)

- Tensile Strength: 95 ksi minimum

- PREN Value: 34-36 (superior pitting resistance)

- Temperature Limit: Up to 300°C (572°F)

- Main Benefits: High strength, excellent chloride stress corrosion cracking resistance, cost-effective

- Common Applications: Oil & gas, chemical processing, marine environments, heat exchangers, pressure vessels

Why It’s Important:

Duplex 2205 solves corrosion problems common to 300 series stainless steels in harsh environments. Its higher strength allows for lighter construction and thinner walls, reducing material costs. The alloy resists chloride stress corrosion cracking up to 150°C (302°F), making it ideal for offshore, chemical processing, and marine applications where 316L would fail.

In demanding sectors like chemical processing, oil and gas, and marine environments, material choice is critical. Duplex 2205 offers a practical middle ground: more corrosion-resistant and stronger than austenitic grades, yet more cost-effective than super duplex alloys for many applications.

I’m Billy Walker, Vice President of James Duva Inc., where we’ve supplied high-grade Duplex 2205 stainless steel products to the power, process, and water treatment industries since 1978. Our experience with Duplex 2205 has shown us how this versatile alloy consistently delivers long-term value in the most challenging industrial environments.

Core Properties and Composition of Duplex 2205

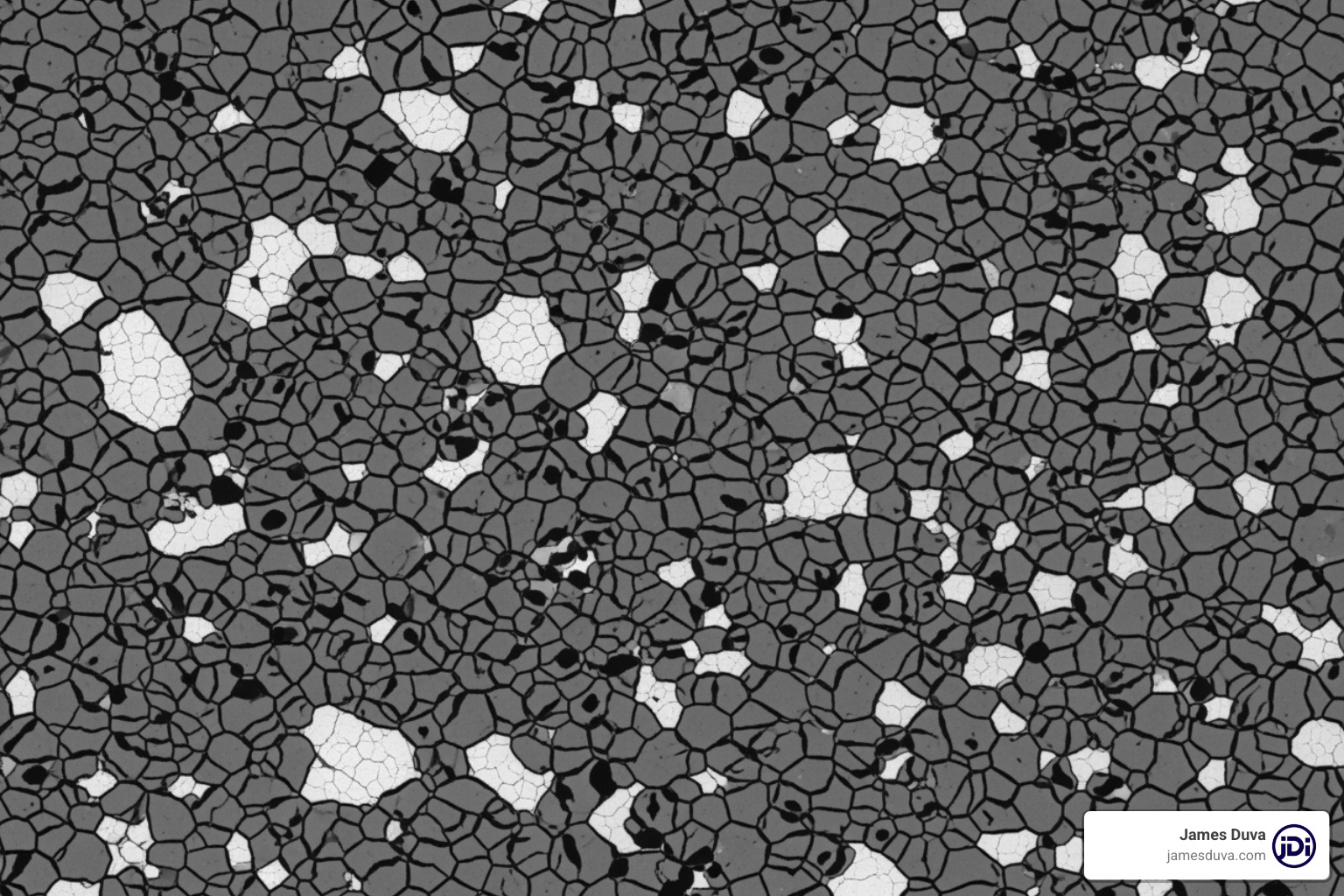

At James Duva Inc., we often explain that the secret behind Duplex 2205‘s exceptional performance lies in its unique dual-phase nature. Unlike traditional stainless steels, which are either predominantly austenitic (like 304 or 316L) or ferritic, Duplex 2205 maintains an approximate 50/50 balance of both. This balanced microstructure is what gives it its name and its remarkable combination of properties.

Duplex 2205 is often referred to by its UNS (Unified Numbering System) designations, primarily UNS S31803 or the more refined UNS S32205. The latter, S32205, is a nitrogen-improved version, offering improved corrosion resistance, especially in the welded condition. This nitrogen improvement is a testament to the continuous innovation in metallurgy, pushing the boundaries of material science to meet the ever-growing demands of industrial applications. For a deeper dive into its advantages, explore our article on Understanding Duplex 2205: Properties, Advantages, and Applications.

Chemical Composition Breakdown

The precise blend of alloying elements in Duplex 2205 is carefully controlled to achieve its desired properties. Our experts at James Duva Inc. understand that even slight variations in composition can significantly impact performance. Here’s a closer look at its key chemical constituents:

- Chromium (Cr): 22% to 23%. This is the primary element for corrosion, oxidation, and pitting resistance.

- Molybdenum (Mo): 3% to 3.5%. It improves pitting and crevice corrosion resistance in chloride environments and adds strength.

- Nickel (Ni): 4.5% to 6.5%. Nickel promotes the austenitic phase, improving ductility, toughness, and corrosion resistance.

- Nitrogen (N): 0.14% to 0.20%. Vital in the S32205 variant, nitrogen improves pitting/crevice corrosion resistance and strength. It also stabilizes the austenite phase, which is crucial for weld zones.

Other elements like Manganese (up to 2.0%), Silicon (up to 1.0%), and small amounts of Carbon (max 0.03%), Phosphorus (max 0.03%), and Sulfur (max 0.02%) are also present, balancing the overall properties.

The effectiveness of this composition is often quantified by the Pitting Resistance Equivalent Number (PREN), a formula that predicts a stainless steel’s resistance to pitting corrosion based on its chromium, molybdenum, and nitrogen content (PREN = %Cr + 3.3 x %Mo + 16 x %N). Duplex 2205 boasts a PREN value typically in the range of 34 to 36, indicating its superior resistance compared to standard austenitic grades. This is one of the many ways How Different Alloys Change Steel’s Properties in stainless steel. Understanding the Stainless Steel Composition is fundamental to appreciating its capabilities.

Key Mechanical Properties of Duplex 2205

Beyond its impressive corrosion resistance, Duplex 2205 is a powerhouse when it comes to mechanical strength. Its dual-phase microstructure provides a unique combination of high strength and ductility.

- High Yield Strength: With a minimum of 65 ksi (448 MPa), Duplex 2205 is nearly twice as strong as 316L. This allows for thinner, lighter designs, saving on material costs and weight.

- High Tensile Strength: A minimum of 95 ksi (655 MPa) indicates a robust ability to withstand significant pulling forces.

- Hardness: Duplex 2205 exhibits a respectable hardness, typically around 293 HB max (or 31 HRC max). This contributes to its wear resistance in various industrial settings.

- Good Fatigue Strength: The alloy also offers good fatigue strength, meaning it can endure repeated cycles of stress without failure, a critical property for components subjected to dynamic loading.

- Ductility: Despite its high strength, Duplex 2205 maintains good ductility, with a minimum elongation of 25% in 2 inches, ensuring it can withstand deformation without brittle fracture under appropriate conditions.

These formidable mechanical properties make Duplex 2205 a superior choice for applications where both strength and durability are paramount. For more on the broader world of materials, check out our guide to Metal Alloys Properties, Types, and Uses.

Physical Properties and Governing Standards

Understanding the physical properties of Duplex 2205 is essential for engineers and designers. These characteristics, combined with its mechanical and corrosion-resistant traits, paint a complete picture of its industrial utility.

- Density: Duplex 2205 has a density of 0.283 lb/in³ (7.800 kg/m³), which is comparable to other stainless steels.

- Thermal Expansion: Its coefficient of thermal expansion is lower than that of austenitic stainless steels, which can be advantageous in applications where thermal distortion needs to be minimized.

- Thermal Conductivity: The thermal conductivity of Duplex 2205 is higher than that of austenitic grades, which can be beneficial in heat exchanger applications.

- Melting Range: The alloy has a melting range typically between 2525-2630°F (1385-1443°C).

To ensure reliability and performance, Duplex 2205 conforms to various international standards and specifications. These include:

- UNS S32205/S31803: The most common designations for this grade.

- ASTM (American Society for Testing and Materials): Specifications cover product forms like A240 (plate, sheet, strip), A790 (pipe), and A928 (welded pipe). ASTM A923 is used to evaluate for intermetallic phases.

- ASME (American Society of Mechanical Engineers): Approved for use in the ASME Boiler and Pressure Vessel Code up to 600°F (316°C). The S32205 variant is approved for nuclear construction.

- EN (Euronorm): Equivalent grade 1.4462.

- NACE (National Association of Corrosion Engineers): Complies with NACE MR0175/ISO 15156 for sour service applications in the oil and gas industry.

At James Duva Inc., we ensure that all our Duplex 2205 products meet these stringent industry standards, providing you with materials you can trust. For more detailed specifications, please refer to our Technical data for Duplex 2205 from James Duva.

Best Corrosion and Heat Resistance

When it comes to industrial applications, material failure due to corrosion or extreme temperatures can be catastrophic. This is where Duplex 2205 truly shines, offering a robust defense against some of the most aggressive environments. From our vantage point in Branchburg, NJ, we’ve seen how crucial superior corrosion resistance is for our clients in the chemical processing and oil & gas sectors.

This image beautifully illustrates the stark difference in performance. While a standard 316L pipe shows signs of severe corrosion in a challenging chloride environment, the Duplex 2205 pipe remains remarkably pristine. This isn’t just a pretty picture; it represents significant cost savings, improved safety, and extended operational life for our customers. Explore more about Corrosion Resistance in our comprehensive resources.

Superior Performance in Corrosive Environments

The high chromium, molybdenum, and nitrogen content in Duplex 2205 provides a formidable shield against various forms of corrosion, making it a go-to material for harsh conditions.

- Chloride Stress Corrosion Cracking (SCC) Resistance: This is a key advantage. Standard austenitic steels (304, 316L) are highly susceptible to SCC in chloride environments. The ferritic phase in Duplex 2205 provides dramatic resistance up to about 150°C (302°F), allowing it to perform where 316L would fail.

- Pitting Resistance: With a PREN value of 34-36, Duplex 2205 offers superior resistance to pitting corrosion compared to 316L and 317L. Its Critical Pitting Temperature (CPT) is around 35°C, making it suitable for many chloride-bearing solutions.

- Crevice Corrosion Resistance: Similar to pitting, the alloy’s composition provides excellent resistance to crevice corrosion, a localized form of attack that occurs in tight spaces where oxygen is depleted.

- General Acid Corrosion: Duplex 2205 demonstrates good resistance to general corrosion in a wide range of organic acids and moderate resistance in dilute reducing acids and moderate to high concentrations of oxidizing acids.

- Sulfide Stress Corrosion (SSC): Its compliance with NACE MR0175/ISO 15156 standards confirms its suitability for sour service applications in oil and gas, indicating strong resistance to SSC.

Our clients in chemical processing plants frequently turn to Duplex 2205 when dealing with aggressive chemicals and high chloride concentrations, a testament to its reliability. For guidance on selecting materials for such demanding settings, read our article on How to Select the Right Stainless Steel Grade for Chemical Processing Plants.

Understanding Heat Resistance and Temperature Limitations

While Duplex 2205 offers remarkable corrosion resistance, it’s crucial to understand its limitations regarding liftd temperatures.

- Service Temperature Limit: Duplex 2205 is not recommended for continuous service above 300°C (572°F). Prolonged exposure above this limit can lead to embrittlement.

- 885°F (475°C) Embrittlement: This occurs when the ferritic phase is exposed to temperatures between 343°C and 538°C (650°F and 1000°F), significantly reducing toughness and ductility. It is best avoided by staying within the recommended service temperature range.

- Sigma Phase Precipitation: Another form of embrittlement, the formation of sigma phase, can occur if Duplex 2205 is exposed to temperatures between 649°C and 1000°C (1200°F and 1830°F). Sigma phase is a brittle intermetallic compound that severely impairs both the mechanical properties and corrosion resistance of the alloy.

- Ductile-to-Brittle Transition at Low Temperatures: Conversely, Duplex 2205 is also not recommended for service below -50°C (-58°F) due to a ductile-to-brittle transition. At very low temperatures, the material’s toughness can decrease significantly.

Despite these limitations, Duplex 2205 offers good oxidation resistance at high temperatures below its embrittlement range. For detailed temperature data and other technical specifications, refer to our Duplex 2205 Technical Data Sheet.

Fabrication and Working with Duplex 2205

Working with Duplex 2205 requires specific knowledge and best practices to ensure its exceptional properties are maintained throughout the manufacturing process. From our facility in Branchburg, NJ, we’ve guided countless clients through the nuances of fabricating this high-performance alloy. While its strength and corrosion resistance are outstanding, its workability demands careful attention.

This image captures the precision and skill required when fabricating Duplex 2205 components. Whether it’s crafting intricate fittings or robust piping systems, understanding the material’s behavior during welding, forming, and machining is paramount. For insights into different types of piping, explore our guide on Seamless Pipe and Welded Pipe: What’s the Difference?.

Welding Procedures and Best Practices

Welding Duplex 2205 is a critical process that, if not managed correctly, can compromise the alloy’s microstructure and properties. The goal is to maintain the balanced ferrite-austenite ratio in the weld metal and heat-affected zone (HAZ) to prevent embrittlement and preserve corrosion resistance.

- Filler Metal Selection: Use matching filler metals like E2209 or ER2209. These have higher nickel content to ensure a balanced phase microstructure in the weld. Welding without filler is not recommended as it can lead to excessive ferrite.

- Low Heat Input Control: Controlling heat input is paramount to prevent detrimental phase formation and ensure proper austenite levels. Maintain heat inputs in the recommended range (e.g., 20-45 kJ/inch for GMAW/GTAW).

- No Pre-heating: Unlike some other high-alloy steels, pre-heating is generally not required for welding Duplex 2205. In fact, it should be avoided, as it can contribute to the formation of undesirable phases.

- Interpass Temperature Control: It’s important to keep the interpass temperature below 150°C (300°F) to minimize the risk of detrimental phase formation.

- Shielding Gas: The addition of a small amount of nitrogen (typically 2-3%) to the shielding gas (e.g., argon) is beneficial. Nitrogen helps to stabilize the austenite phase and improve the corrosion resistance of the weld.

- Post-weld Heat Treatment: A post-weld heat treatment (PWHT) is generally not required and, in most cases, should be avoided, as it can promote embrittlement. If severe cold deformation has occurred and SCC is a concern, a full anneal (solution treatment) between 1020-1100°C (1868-2012°F) followed by rapid cooling (water quench) may be necessary.

Proper welding techniques are vital for the integrity of components like Butt Weld Fittings: Types, Applications, and Benefits made from Duplex 2205.

Forming and Machinability Characteristics of Duplex 2205

The high strength of Duplex 2205 presents both advantages and challenges during forming and machining operations.

- Hot Forming: Duplex 2205 can be hot formed, typically within a temperature range of 1100°C to 1150°C (2010°F to 2100°F). It’s crucial to ensure uniform heating and avoid forging below 950°C (1740°F) to prevent cracking. After hot forming, components should be solution annealed and rapidly quenched to restore optimal properties.

- Cold Forming: Duplex 2205‘s high strength requires greater force for cold forming. Designers must account for higher spring-back and use generous bend radii (at least 2x material thickness) to prevent cracking. Heavy cold work may require an intermediate anneal.

- Machinability: Machinability is low due to high strength and work hardening. Cutting speeds are about 20% lower than for 304 stainless steel. To achieve good results, we advise:

- Using rigid, powerful machinery.

- Employing sharp, robust tooling (carbide tools are often preferred).

- Minimizing tool extension to reduce vibration.

- Using appropriate cutting fluids.

- Designing cutting sequences to cut below the work-hardened layer from previous passes.

- Work Hardening: Duplex 2205 exhibits a degree of work hardening, which can be beneficial in some applications but needs to be managed during fabrication.

For applications requiring precise shapes, such as Industrial Tubing: A Down-to-Earth Guide to Seamless and Welded Tubing Solutions, understanding these forming characteristics is vital.

Applications and Comparative Analysis

The unique combination of high strength and excellent corrosion resistance makes Duplex 2205 an invaluable material across a diverse range of industries. From our base in Branchburg, NJ, James Duva Inc. proudly supplies Duplex 2205 to clients operating in some of the most demanding environments imaginable.

Here are some of the key industries that extensively use Duplex 2205:

- Oil & Gas Industry: For components exposed to corrosive sour gas and chloride-rich seawater, including offshore platforms, oil field piping, heat exchangers, and separators.

- Chemical Processing: Used in pressure vessels, tanks, piping, heat exchangers, and other equipment handling aggressive chemicals.

- Marine Environments: Ideal for shipbuilding, offshore structures, and marine hardware due to its resistance to saltwater corrosion.

- Pulp & Paper Industry: Employed in digesters, bleaching equipment, and stock-handling systems where corrosive chemicals are present.

- Desalination Plants: Critical for water treatment equipment, particularly for seawater reverse osmosis (RO) systems, where chloride resistance is paramount.

- Biofuels Plants: Used in various process components where corrosion resistance to organic acids is needed.

- Food Processing: For equipment requiring high hygiene standards and resistance to cleaning agents.

- Effluent Scrubbing Systems: For handling corrosive flue gases.

Common products fabricated from Duplex 2205 include:

- Heat exchangers

- Pressure vessels

- Piping and tubing

- Tanks and storage vessels

- Flanges and fittings

- Pump shafts

- Cargo tanks for ships and trucks

- Scrubbers and effluent systems

For a broader perspective on where stainless steel makes a difference, check out our article on Stainless Steel Applications for Every Industry.

Duplex 2205 vs. Other Stainless Steel Grades

Choosing the right stainless steel grade is a critical decision, and often, Duplex 2205 emerges as the optimal choice, balancing performance and cost. Let’s compare it to some other common grades:

| Property | Duplex 2205 | 316L (Standard Austenitic) | Higher-Alloy Duplex (e.g., 2507) |

|---|---|---|---|

| Yield Strength | 65 ksi min (More than double 316L) | 30 ksi min (Standard strength) | 80 ksi min (Even higher than 2205) |

| Tensile Strength | 95 ksi min | 75 ksi min | 116 ksi min |

| PREN Value | 34-36 (Excellent pitting & crevice resistance) | 25-28 (Good pitting & crevice resistance) | >40 (Superior pitting & crevice resistance) |

| Chloride SCC | Excellent resistance (up to 150°C/302°F) | Poor resistance (highly susceptible) | Excellent resistance (higher temperatures/conc.) |

| Cost-Effectiveness | High performance for moderate severity, good value | Lower initial cost, but higher lifecycle in harsh conditions | Higher initial cost, but best for extreme severity |

| Temperature Limit | -50°C to 300°C (-58°F to 572°F) | Cryogenic to 450°C (842°F) | -50°C to 280°C (-58°F to 536°F) |

- Versus 316L: Duplex 2205 is a significant upgrade in strength and corrosion resistance. Its superior resistance to SCC, pitting, and crevice corrosion makes it more reliable in chloride environments where 316L fails. Its higher strength also allows for lighter designs.

- Versus Higher-Alloy Duplex Grades (e.g., Super Duplex 2507): Super duplex grades offer even higher corrosion resistance (PREN > 40) and strength but at a higher cost. Duplex 2205 is often the more cost-effective choice for applications where its properties are sufficient, hitting a sweet spot between performance and cost. For a more detailed comparison, refer to our article Duplex 2205 vs Higher-Alloy Duplex Grades for Industrial Applications.

Available Forms and Cost-Benefit Analysis

At James Duva Inc., we understand that material availability in various forms is crucial for diverse industrial projects. We offer Duplex 2205 in a comprehensive range of product forms to meet your specific needs:

- Pipe: Seamless and welded pipe for fluid transport.

- Tube: Seamless and welded tubing for heat exchangers and instrumentation.

- Bar: Round, square, and flat bars for structural components and machining.

- Plate: For pressure vessels, tanks, and structural fabrication.

- Sheet: For lighter gauge applications and fabrication.

- Fittings: Buttweld, forged, and sanitary fittings for piping systems.

- Flanges: Weld neck, slip-on, blind, and other flange types for pipe connections.

These various forms ensure that Duplex 2205 can be incorporated into virtually any industrial design. For details on our extensive range of products, including Flanges, Fittings, and Pipes: The Advantages of Premium Stainless Steel Materials, please reach out to our team in Branchburg, NJ.

From a cost perspective, choosing Duplex 2205 involves a thorough cost-benefit analysis:

- Higher Initial Cost: Duplex 2205 typically has a higher initial material cost per pound compared to standard austenitic stainless steels like 316L. This is due to its higher alloy content.

- Lower Lifecycle Cost: Despite a higher initial cost, Duplex 2205 often has a lower lifecycle cost. Its superior corrosion resistance means longer service life, less maintenance, and fewer replacements, which minimizes downtime and related expenses.

- Weight Savings: Its high yield strength allows for thinner walls and lighter components. This can reduce material, fabrication, transportation, and installation costs, especially for large or offshore structures.

- Improved Safety and Reliability: In critical applications, the cost of failure (environmental damage, safety hazards, catastrophic equipment loss) far outweighs the material cost. Duplex 2205 provides a higher margin of safety and reliability, preventing costly incidents.

While the initial price tag might be higher, the long-term economic benefits and improved performance of Duplex 2205 make it a prudent investment for challenging industrial environments.

Frequently Asked Questions about Duplex 2205

We often receive questions about Duplex 2205 from engineers and project managers looking for reliable material solutions. Here, we address some of the most common inquiries.

Why is Duplex 2205 so much stronger than 316L stainless steel?

The strength of Duplex 2205 comes from its two-phase microstructure, combining the properties of austenite and ferrite. The ferritic phase provides high strength, while the austenitic phase offers ductility. Nitrogen is added to further strengthen the material and help maintain the balanced microstructure. This results in a yield strength more than double that of 316L, allowing for thinner, lighter designs.

Can you use Duplex 2205 in high-temperature applications?

Duplex 2205 is not recommended for continuous service above 300°C (572°F). Prolonged exposure to higher temperatures can cause embrittlement due to the formation of brittle micro-constituents (like sigma phase). This significantly reduces the material’s toughness, ductility, and corrosion resistance. While it has good oxidation resistance below this limit, its mechanical properties are compromised at liftd temperatures. Other specialized alloys are better for sustained high-temperature use.

What is the main difference between Duplex 2205 and higher-alloy duplex grades?

The main difference is alloy content and corrosion resistance. Higher-alloy grades like Super Duplex 2507 have more chromium, molybdenum, and nitrogen. This gives them a higher PREN value (>40 vs. 34-36 for Duplex 2205), providing superior resistance to pitting and crevice corrosion in extremely aggressive environments. While Duplex 2205 is excellent for many conditions, Super Duplex is for the most challenging applications where its higher cost is justified.

Conclusion

Duplex 2205 stainless steel offers a powerful combination of high strength, excellent corrosion resistance, and good fabricability, making it a reliable and cost-effective solution for challenging industrial environments. Its unique properties allow for lighter, more durable designs where standard stainless steels would fail. For expert guidance and a reliable supply of high-quality Duplex 2205 products, trust the specialists at James Duva Inc. to meet your project’s demanding specifications. Explore our extensive inventory of industrial fittings today.

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.