Deciphering the Duel: Duplex 2205 vs. Super Duplex 2507 for Industrial Applications

Mar 22, 2024

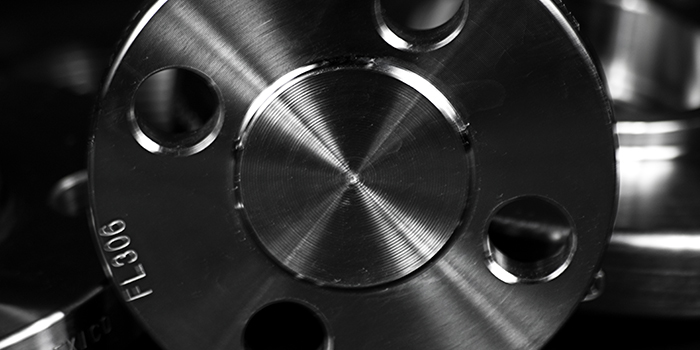

In industries where corrosive environments, high pressures, and extreme temperatures are the norm, selecting the right stainless steel grade is critical. Duplex 2205 and Super Duplex 2507 are two high-performance alloys frequently chosen for demanding applications across offshore, chemical, desalination, and process industries.

What Is Duplex Stainless Steel?

Duplex stainless steels combine austenitic and ferritic microstructures to balance strength, toughness, and corrosion resistance. Grade Duplex 2205 (UNS S32205 / S31803) is one of the most widely used duplex alloys thanks to its robust performance and cost-effective profile.

Duplex 2205 typically contains chromium, nickel, molybdenum, and nitrogen — giving it strong resistance to chloride stress corrosion cracking and excellent mechanical properties in many industrial environments.

Super Duplex 2507: Elevated Performance

Super Duplex 2507 (UNS S32750) is formulated with higher levels of chromium, molybdenum, and nitrogen, resulting in a Pitting Resistance Equivalent Number (PREN) above 40 — a key indicator of enhanced resistance to pitting and crevice corrosion in aggressive environments like seawater and chemical processing.

Its increased strength and stress corrosion cracking resistance make 2507 ideal for high-pressure systems, subsea equipment, and offshore platforms where performance demands exceed those of standard duplex grades.

Corrosion Resistance: 2205 vs 2507

| Property | Duplex 2205 | Super Duplex 2507 |

| PREN (Pitting Resistance) | ~34–36 | ~40–45 |

| Chloride Environment Performance | Strong | Exceptiona |

| Best For | Moderate chloride & industrial use | Severe offshore & marine conditions |

Duplex 2205 performs exceptionally well in environments with moderate chloride exposure and is widely used in chemical process piping, marine equipment, and industrial heat exchangers. Super Duplex 2507, with its higher PREN, excels in deep-sea, desalination, and high stress applications where corrosion threats are extreme.

Mechanical Strength & Fabrication

Both alloys exhibit significantly higher strength compared to traditional austenitic grades like 316L. Duplex 2205’s strong yield and tensile strength make it suitable for many structural and pressure-bearing applications, while Super Duplex 2507’s increased strength allows for thinner section designs and improved service life where durability is paramount.

Welding both materials requires careful heat input control to preserve the duplex microstructure, with Super Duplex 2507 often needing specialized filler metals and tighter process control.

Cost & Material Selection

Duplex 2205 is generally more cost-effective due to its balanced alloy content and broad availability. Super Duplex 2507 commands a higher price but delivers superior corrosion resistance and mechanical properties that can reduce long-term maintenance and lifecycle costs in demanding environments.

Frequently Asked Questions

1. What is the primary difference between Duplex 2205 and Super Duplex 2507?

Duplex 2205 has lower chromium, molybdenum, and nitrogen content and a PREN typically ~34–36, making it strong and corrosion-resistant for many industrial uses. Super Duplex 2507 has higher alloying levels with a PREN above 40, offering superior resistance for extreme environments.

2. Which alloy is best for marine and offshore applications?

Super Duplex 2507 is usually preferred in harsh marine and offshore applications due to its exceptional resistance to pitting and crevice corrosion and high mechanical strength.

3. Can these steels be welded easily?

Both can be welded, but controlling heat input and interpass temperatures is crucial to maintaining corrosion resistance and mechanical properties. Super Duplex 2507 often requires more specialized welding techniques.

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.