Dive Deep into Monel 400: Everything You Need to Know About Its Many Forms

Jan 26, 2026

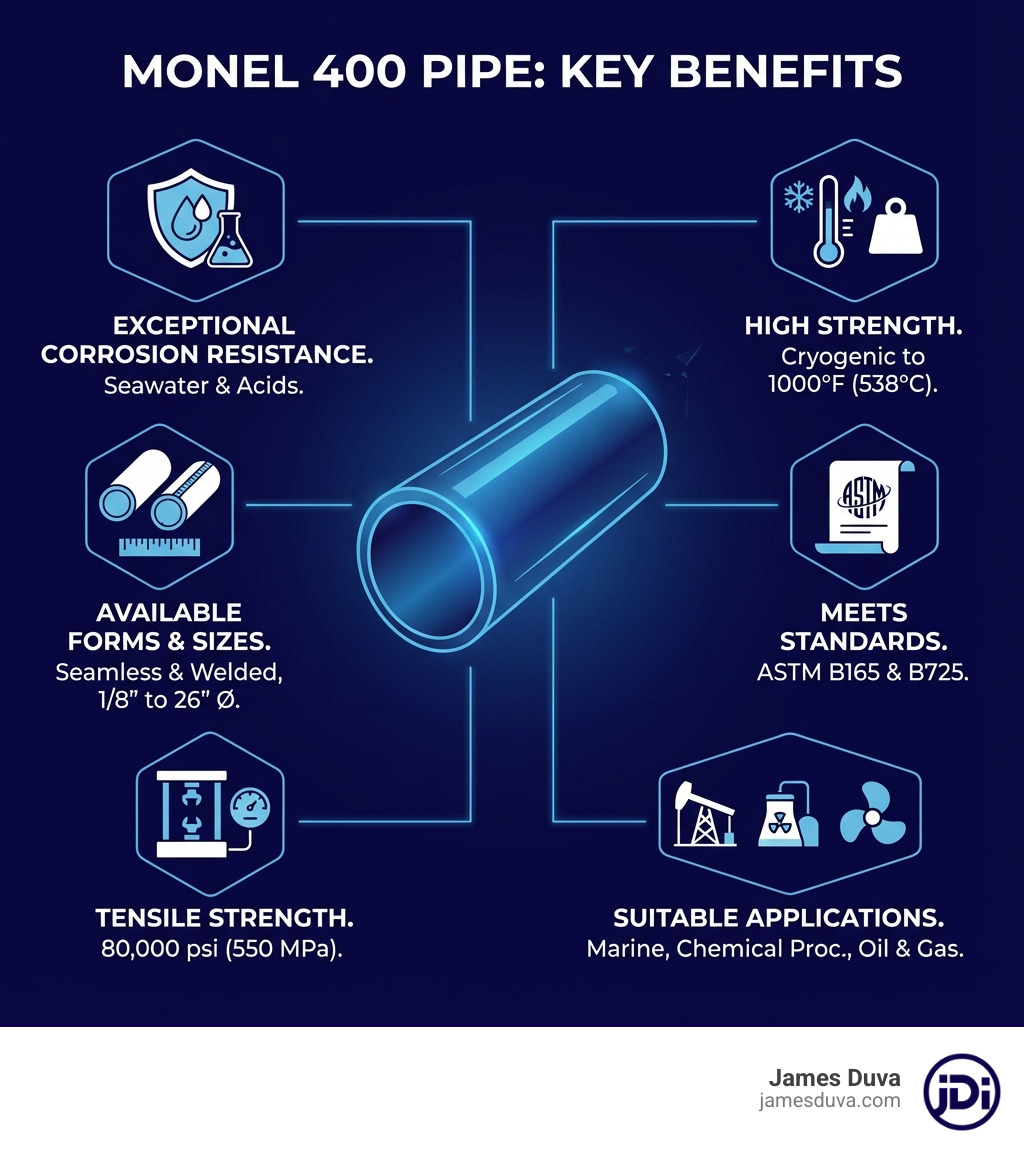

Why Monel 400 Pipe Matters for Critical Industrial Applications

Monel 400 pipe is a nickel-copper alloy engineered for extreme environments where standard materials fail. If you’re sourcing pipe for corrosive or high-performance applications, here’s what you need to know:

- Composition: 63% minimum nickel, 28-34% copper

- Temperature Range: Cryogenic temperatures up to 1000°F (538°C)

- Available Forms: Seamless or welded construction

- Size Range: 1/8″ to 26″ diameter

- Schedules: Sch. 5 through Sch. XXH

- Key Standards: ASTM B165, ASME SB165, ASTM B725

- Tensile Strength: 80,000 psi (550 MPa) in annealed condition

- Primary Applications: Marine engineering, chemical processing, oil and gas

The alloy’s exceptional resistance to seawater, hydrofluoric acid, sulfuric acid, and alkalies has made it an industry standard for over 100 years. Unlike many materials that compromise either strength or corrosion resistance, Monel 400 delivers both across an impressive temperature spectrum.

This guide breaks down everything you need to understand about Monel 400 pipe forms, specifications, and applications. We’ll cover the technical properties that make this alloy unique, the various product forms available, and the specific industries where it solves critical challenges.

Whether you’re specifying materials for a chemical processing plant, designing marine systems, or replacing corroded infrastructure, understanding your options for Monel 400 pipe will help you make informed sourcing decisions.

I’m Billy Walker, Vice President of James Duva Inc., and I’ve spent decades helping industrial clients source high-grade Monel 400 pipe and specialty alloys for demanding applications. Our team works directly with leading manufacturers to ensure you get the right specifications, certifications, and delivery timelines for your projects.

What is Monel 400? An Overview of its Unique Characteristics

At James Duva Inc., we often get asked, “What exactly makes Monel 400 so special?” Well, Monel 400 is a remarkable nickel-copper alloy, often referred to as a “puritan alloy” because its nickel and copper content are roughly equal, mirroring the composition of naturally occurring nickel ore. This unique blend grants it an impressive suite of characteristics that set it apart in demanding industrial environments.

It’s a solid-solution alloy, meaning its strength comes from the uniform distribution of its constituent elements. This also means it can only be hardened through cold-working, a key distinction from alloys that rely on heat treatment for strength. This inherent high strength is coupled with excellent toughness, making it a robust choice for applications where both mechanical integrity and durability are paramount.

One of Monel 400’s most celebrated attributes is its exceptional Corrosion Resistance. It stands up valiantly against a wide array of aggressive media, including flowing seawater, brackish water, hydrofluoric acid, sulfuric acid, and various alkalies. This makes it a go-to material when other alloys would simply succumb to the harsh realities of corrosive environments.

When comparing it to pure nickel, Monel 400 offers a lower-cost alternative while retaining very similar characteristics to Nickel 200/201, providing a cost-effective solution without compromising performance. For more on how such materials contribute to industrial resilience, explore our guide on Metal Alloys: Properties, Types, and Uses.

Chemical Composition and Core Properties

The magic of Monel 400 truly lies in its carefully balanced chemical composition. Our Monel 400 pipe (UNS N04400, also known as Werkstoff Nr. 2.4360 or 2.4361) is predominantly composed of nickel and copper, with precise limits on other elements to ensure its superior performance.

Here’s a closer look at its typical limiting chemical composition:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 63.0 min. |

| Copper (Cu) | 28.0 – 34.0 |

| Iron (Fe) | 2.5 max. |

| Manganese (Mn) | 2.0 max. |

| Silicon (Si) | 0.5 max. |

| Carbon (C) | 0.3 max. |

| Sulfur (S) | 0.024 max. |

Beyond its chemical makeup, Monel 400 boasts impressive physical properties. It has a density of 8.8 g/cm³ (0.318 lb/in³), which is quite substantial, reflecting its robust nature. Its melting point ranges from 1300-1350°C (2370-2460°F), indicating its stability at high temperatures. Furthermore, it exhibits good thermal conductivity, for instance, around 18.92 kcal/(hr.m.°c) at 21.1°C, allowing for efficient heat transfer in applications like heat exchangers. It is also generally non-magnetic, a useful trait in certain specialized applications. For a deeper dive into these characteristics, check out our article on Monel 400 UNS N04400: Properties, Applications, and Benefits.

Mechanical Strength and Temperature Range

When it comes to raw power, Monel 400 pipe doesn’t disappoint. In its annealed condition, it offers a formidable tensile strength of 80,000 psi (550 MPa) and a yield strength of 35,000 psi (240 MPa), with an elongation of 40%. These figures underscore its ability to withstand significant stress and deformation without fracturing. While its strength is relatively low in the annealed state, it can be significantly increased through cold-working, a process we employ to tailor the material to specific application needs.

But what truly sets Monel 400 apart is its exceptional performance across an astonishing temperature spectrum. It retains its strength and toughness at extremely low, cryogenic temperatures, making it invaluable for applications in liquefied gas processing. On the other end of the thermometer, it remains effective at temperatures as high as about 1000°F (538°C). This remarkable thermal versatility means that a single material can handle environments ranging from the freezing depths of industrial refrigeration to the scorching heat of process piping. When you need materials that perform under such diverse thermal stresses, understanding When to Choose Nickel Alloys Over Stainless Steel in Industrial Applications becomes critical.

Understanding Monel 400 Pipe: Forms, Sizes, and Specifications

At James Duva Inc., we understand that one size rarely fits all. That’s why we ensure that Monel 400 pipe is available in a variety of forms, sizes, and specifications to meet the diverse needs of our clients in Branchburg, NJ, and beyond. This robust alloy, identified by its UNS N04400 designation and Werkstoff Nr. 2.4360 or 2.4361, is a cornerstone of our inventory, ready to tackle your toughest projects. Our extensive stock of pipes reflects our commitment to providing custom solutions.

Available Forms of Monel 400 Pipe

The manufacturing flexibility of Monel 400 allows for its production into various pipe forms, each suited for different application demands:

- Seamless Pipe: Ideal for high-pressure applications where structural integrity is paramount. Our seamless Monel 400 pipe typically ranges from ½” to 8″ in diameter and is available in schedules like 10s, 40s, 80s, 160, and XXH.

- Welded Pipe: Often a more cost-effective option for applications where seamless construction isn’t strictly necessary. We offer welded Monel 400 pipe in sizes from 8″ to 12″, with schedules such as 10s and 40s. These can include Electric Resistance Welded (ERW) or Electric Fusion Welded (EFW) types.

- Other Forms: While round pipe is the most common, Monel 400 can also be found in other forms like tubing, which may include square and rectangular profiles, depending on specific project requirements.

Understanding the distinctions between these forms is crucial for optimal material selection. For a more detailed comparison, you might find our article on Seamless Pipe and Welded Pipe: What’s the Difference particularly helpful.

Common Standards for Monel 400 Pipe

When sourcing Monel 400 pipe, adhering to recognized industry standards is non-negotiable. These standards ensure the material’s quality, consistency, and performance. We proudly supply Monel 400 products that meet or exceed the following common specifications:

- ASTM B165 / ASME SB165: Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube.

- ASTM B725: Standard Specification for Welded Nickel (UNS N02200) and Nickel-Copper Alloy (UNS N04400) Pipe.

- ASTM B775: Standard Specification for General Requirements for Nickel and Nickel Alloy Welded Pipe.

- ASTM B829: Standard Specification for General Requirements for Nickel and Nickel-Cobalt Alloy Seamless Pipe and Tube.

- ASTM B163: Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes.

- NACE MR-01-75: This standard is particularly relevant for oil and gas service, outlining requirements for sulfide stress cracking resistant metallic materials for oilfield equipment.

We also ensure compliance with other international standards where applicable, as well as specific client requirements. When specifying nickel alloy products, always refer to the UNS number for precise material identification. For all your requirements in Stainless and Nickel Alloy Piping Products, we’ve got you covered.

Sizes, Dimensions, and Schedules

The versatility of Monel 400 pipe extends to its wide range of available sizes and dimensions, ensuring it can be custom to virtually any industrial piping system. From the smallest instrumentation lines to large-bore process piping, Monel 400 delivers.

Our inventory includes:

- Pipe Sizes: From a compact 1/8″ nominal pipe size (NPS) up to a substantial 26″ NPS. This broad range allows for precise fitting into diverse system designs.

- Schedules: We offer a comprehensive selection of wall thicknesses, indicated by schedules, ranging from the lighter Sch. 5 and Sch. 10 to the heavier Sch. 40, Sch. 80, Sch. 160, and even Sch. XXH (double extra heavy). These schedules dictate the pipe’s pressure rating and durability, allowing us to match the right pipe to your specific operating conditions.

- Lengths: Standard lengths are typically available, and custom lengths can often be sourced to minimize waste and fabrication time.

- End Types: Pipes can be supplied with various end preparations, including plain, beveled for welding, or threaded, depending on the connection method required.

This extensive range means that whether you need thin-walled tubing for heat exchange or heavy-duty piping for high-pressure corrosive lines, there’s a Monel 400 pipe configuration for you.

Key Applications and Fabrication of Monel 400

It’s one thing to talk about the impressive properties of Monel 400; it’s another to see it in action, solving real-world industrial challenges. The combination of high strength, excellent corrosion resistance, and broad temperature suitability makes Monel 400 pipe an indispensable material across numerous critical applications. As experts in Nickel Alloys, we’ve seen Monel 400 rise to the occasion time and again.

Industries Served

Monel 400’s robust characteristics make it a preferred material in industries where failure is not an option:

- Marine Engineering: Its superior resistance to rapidly flowing brackish water and seawater makes it ideal for marine fixtures, pump and propeller shafts, and saltwater piping systems on ships and offshore platforms. It has been a staple in marine applications for over 100 years.

- Chemical Processing: Resistant to hydrofluoric acid, sulfuric acid, and various alkalies, Monel 400 pipe is extensively used in chemical and hydrocarbon processing equipment, including process vessels, heat exchanger piping, and storage tanks for gasoline and potable water.

- Oil and Gas: From petroleum distillation tower internals and fasteners to process piping, Monel 400’s resilience to corrosive crude and processing chemicals is highly valued.

- Aerospace: Its high mechanical properties, ductility, and resistance to atmospheric corrosion make it suitable for components like rivets in aluminum-skinned aircraft construction. Learn more about Nickel-Based Alloys in the Aerospace Industry.

- Power Generation: Used in boiler feedwater heaters and other heat exchangers, especially where steam at liftd temperatures is present.

- Specialized Applications: The spark-free nature of Monel 400 also makes it suitable for high-risk situations in the explosives industry, rocketry, and pulp and paper processing, where safety is paramount.

Common Use Cases

Within these industries, Monel 400 pipe and related products are found in critical components:

- Heat Exchangers: Due to its excellent thermal conductivity and corrosion resistance, it’s perfect for transferring heat in corrosive media.

- Process Vessels and Piping Systems: Essential for containing and transporting corrosive chemicals, acids, and alkalies.

- Pump Shafts, Valves and Pumps: Its strength and corrosion resistance make it ideal for internal components exposed to aggressive fluids.

- Marine Fixtures and Fasteners: Ensuring longevity and structural integrity in harsh saltwater environments.

- Gasoline and Freshwater Tanks: Providing reliable storage solutions without corrosion.

- Brine Heaters and Salt Production Equipment: Withstanding highly saline and corrosive conditions.

Historically, Monel 400 has been employed for over a century in petroleum distillation tower internals, fasteners, and fittings, proving its enduring reliability.

Welding and Machinability

Working with high-performance alloys like Monel 400 requires expertise, especially when it comes to fabrication. While Monel 400 pipe is generally considered readily weldable, it’s not quite like welding carbon steel. Specific considerations are crucial to ensure the integrity and performance of the final product.

- Welding Considerations: To avoid issues like hot cracking, low-heat input techniques are recommended. We advise using appropriate filler metals such as AWS A5.14 ERNiCu-7 weld wire and AWS A5.11 ENiCu-7 weld wire. These consumables are specifically designed to complement Monel 400’s composition and properties. Unlike some other alloys, post-weld heat treatment is generally not required for Monel 400 pipe to maintain its corrosion resistance, simplifying fabrication processes. However, annealing might be performed for complex fabrications to relieve stress.

- Machinability: Monel 400 can be machined, but its high strength and toughness mean it requires robust tooling, slower speeds, and adequate lubrication to achieve optimal results and extend tool life. Skilled machinists are key to successful fabrication.

For components like butt weld fittings, which form the backbone of durable and high-performance piping systems, proper welding techniques are paramount. You can explore more about these essential components in our article on Butt Weld Fittings: The Backbone of Durable and High-Performance Piping Systems.

Frequently Asked Questions about Monel 400 Pipe

We know that choosing the right material for your project can sometimes feel like navigating a maze. To help you along, here are some of the most common questions we receive about Monel 400 pipe, answered by our experts.

What makes Monel 400 so resistant to corrosion?

Monel 400’s exceptional corrosion resistance stems from its unique nickel-copper composition. The high content of both nickel (min. 63%) and copper (28-34%) creates a robust alloy that forms a stable passive film on its surface when exposed to corrosive media. This film acts as a protective barrier. It provides outstanding resistance to a wide array of aggressive environments, including:

- Seawater and Brackish Water: It exhibits superior resistance to flowing seawater and brackish water, making it a marine engineering favorite.

- Acids: It stands up well against non-oxidizing acids like hydrofluoric acid and sulfuric acid, especially in deaerated conditions.

- Alkalies: Strong resistance to various alkaline solutions.

- Salt Solutions: Excellent performance in neutral and alkaline salt solutions.

- Reducing Environments: It performs particularly well in reducing environments and is highly resistant to stress corrosion cracking, a common failure mode in many other alloys.

Can Monel 400 be used in high-temperature applications?

Absolutely! One of the remarkable features of Monel 400 pipe is its impressive thermal versatility. It maintains good strength and toughness not only at room temperature but also at liftd temperatures, remaining effective up to approximately 1000°F (538°C). This makes it suitable for applications involving hot steam, heat exchangers, and process piping in high-temperature chemical environments.

Equally important, Monel 400 also performs exceptionally well at the other end of the spectrum: sub-zero and cryogenic temperatures. This dual capability—maintaining integrity from freezing cold to scorching hot—makes it a highly versatile alloy for a wide range of thermal applications where consistent performance is critical.

Is Monel 400 pipe difficult to weld?

While Monel 400 pipe is considered readily weldable, it does require specific procedures and careful attention to detail, which is typical for high-nickel alloys. It’s not inherently “difficult” for experienced welders, but it’s crucial to follow best practices to ensure the integrity of the weld and prevent defects like hot cracking.

Key considerations include:

- Low-Heat Input: Using welding techniques that minimize heat input helps control the weld pool and reduce the risk of cracking.

- Appropriate Filler Metals: We recommend using specific filler metals such as AWS A5.14 ERNiCu-7 weld wire or AWS A5.11 ENiCu-7 weld wire, which are designed to match Monel 400’s properties.

- Cleanliness: Maintaining a clean weld area is essential to prevent contamination.

A significant advantage is that post-weld heat treatment is generally not required for Monel 400 pipe to restore its corrosion resistance, which can simplify fabrication processes and reduce overall project time and cost. For complex fabrications, annealing after welding may be performed to relieve residual stresses from cold working.

Your Source for High-Performance Nickel Alloys

When your project demands the unwavering performance of Monel 400 pipe and other high-grade specialty alloys, you need a partner you can trust. At James Duva Inc., based right here in Branchburg, NJ, we pride ourselves on being that reliable, one-stop solution for industries that simply cannot compromise on material quality.

With decades of expertise since 1978, our team understands the intricate demands of chemical processing, oil & gas, marine engineering, and many other critical sectors. We don’t just supply materials; we provide solutions, helping you steer complex project requirements and ensuring you receive precisely what you need, when you need it.

Our commitment extends beyond just inventory. We offer technical expertise, working with you to identify the correct specifications, certifications, and logistical planning to keep your projects on track. For comprehensive solutions and a vast inventory of Monel 400 and other high-performance materials, explore our full range of nickel alloys.

Let us be your trusted partner in sourcing high-quality alloys. Find how easy it can be with our One-Stop Solution: Sourcing Stainless Steel and Nickel Alloy Products Made Easy.

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.