Exploring the Applications of Hastelloy C-276: Versatility in Industrial Solutions

Jul 12, 2024

Introduction

Hastelloy C-276, a nickel-molybdenum-chromium superalloy renowned for its exceptional corrosion resistance and high temperature stability, plays a pivotal role across a spectrum of industries. Developed by Haynes International, Inc., this alloy has become indispensable in environments where conventional metals would succumb to corrosion or thermal degradation. Its composition, which includes nickel (for corrosion resistance), molybdenum (enhancing resistance to reducing media), and chromium (contributing to oxidation resistance), makes Hastelloy C-276 a preferred choice for demanding applications.

Understanding the versatile applications of Hastelloy C-276 is crucial for industries seeking durable and reliable materials for critical infrastructure. This blog explores its diverse uses across various sectors, highlighting its unique properties that ensure longevity and operational safety.

Chemical Processing Industry

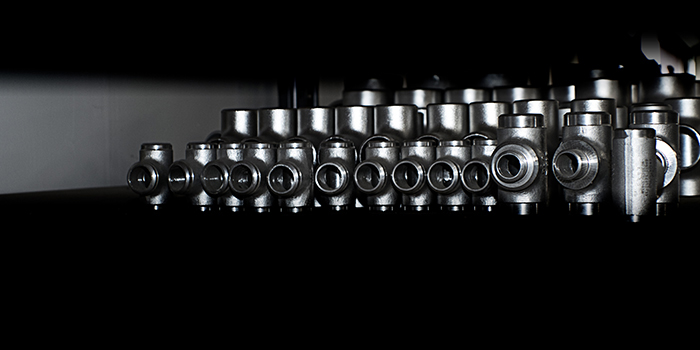

In the chemical processing industry, where handling corrosive chemicals and acids is routine, Hastelloy C-276 shines as a corrosion-resistant solution. Its ability to withstand a wide range of aggressive environments makes it ideal for applications such as chemical reactors, piping systems, and storage tanks. These components are often exposed to acids, chlorides, and other corrosive substances that would rapidly degrade conventional metals. Hastelloy C-276 not only maintains structural integrity but also ensures product purity and operational safety by preventing contamination and leaks.

Moreover, in pharmaceutical manufacturing, where stringent purity standards are paramount, Hastelloy C-276 finds extensive use in reactors and vessels. Its non-reactive nature with pharmaceutical compounds and resistance to corrosion from cleaning agents and process chemicals make it indispensable for maintaining sanitary conditions and product integrity.

Oil and Gas Sector

In the oil and gas sector, particularly offshore and refinery environments, Hastelloy C-276 addresses the challenges posed by corrosive seawater, acidic gases, and high-pressure conditions. It is employed in critical components such as pipelines, valves, and heat exchangers where durability and reliability are non-negotiable. Offshore platforms, exposed to harsh marine environments, benefit from Hastelloy C-276’s resistance to pitting and crevice corrosion, ensuring long-term structural integrity and operational uptime.

Refinery equipment, which handles corrosive fluids and high-temperature processes, also relies on Hastelloy C-276 for its ability to maintain performance under extreme conditions. Its resistance to sulfide stress cracking and oxidation at elevated temperatures enhances the safety and efficiency of oil refining operations.

In summary, Hastelloy C-276’s versatility in the chemical processing, pharmaceutical, and oil and gas industries underscores its value as a material that ensures both performance and reliability in challenging environments.

Aerospace and Defense Uses

Hastelloy C-276 plays a critical role in the aerospace and defense sectors, where its combination of strength, corrosion resistance, and lightweight properties is highly valued. In aerospace applications, the alloy is used in components subjected to high stress and extreme conditions, such as aircraft turbines, engine exhaust systems, and structural elements. Its ability to withstand elevated temperatures and corrosive environments encountered during flight ensures the safety and reliability of aircraft operations.

Within the defense industry, Hastelloy C-276 is utilized in military vehicles, missile systems, and naval vessels. Its resistance to seawater corrosion and ballistic impact, coupled with its durability under harsh environmental conditions, makes it an ideal choice for protecting critical equipment and structures. The alloy’s reliability in both static and dynamic military applications underscores its importance in ensuring national security and defense readiness.

Power Generation

The power generation sector relies on Hastelloy C-276 for components that operate in high-temperature and corrosive environments typical of steam turbines, boilers, and nuclear reactors. Its resistance to oxidation and chloride stress corrosion cracking makes it suitable for applications where steam and high-pressure water are prevalent. Hastelloy C-276 components contribute to the efficiency and longevity of power plants by maintaining operational integrity and minimizing downtime due to corrosion-related failures.

In nuclear power plants, where safety and reliability are paramount, Hastelloy C-276 is used in reactor vessels, fuel storage systems, and control rod mechanisms. Its ability to withstand radiation exposure and corrosive coolant environments ensures the continued safe operation of nuclear facilities. The alloy’s performance in maintaining structural integrity under extreme conditions contributes to the overall safety and sustainability of nuclear power generation.

Marine and Shipbuilding

In marine environments, Hastelloy C-276 is valued for its resistance to corrosion from seawater, making it an ideal material for marine applications. Shipbuilders use Hastelloy C-276 in critical components such as ship hulls, propeller shafts, and desalination plants. Its durability and reliability under constant exposure to saltwater environments help extend the service life of marine vessels and infrastructure.

Desalination plants, which convert seawater into potable water, benefit from Hastelloy C-276’s corrosion resistance in high-chloride environments. The alloy’s ability to withstand brine solutions and aggressive chemicals used in water treatment processes ensures efficient and reliable operation of desalination facilities, supporting global efforts to secure freshwater resources.

In summary, Hastelloy C-276’s applications in aerospace and defense, power generation, and marine sectors demonstrate its versatility and reliability in demanding industrial environments. Its unique properties contribute to enhanced performance, durability, and safety across various critical infrastructure applications.

Food and Beverage Industry

In the food and beverage industry, where hygiene and product purity are paramount, Hastelloy C-276 is utilized in critical equipment such as storage tanks, heat exchangers, and processing machinery. The alloy’s resistance to corrosion from acidic foods, cleaning agents, and sanitizing solutions ensures compliance with stringent food safety regulations. Hastelloy C-276’s non-reactive properties prevent contamination and maintain product integrity, making it an ideal choice for maintaining sanitary conditions and ensuring the quality of food and beverage products.

Semiconductor Manufacturing

Semiconductor manufacturing requires ultra-clean environments and precise control over chemical processes. Hastelloy C-276 is employed in semiconductor manufacturing equipment such as chemical handling systems, process chambers, and exhaust ducts. Its corrosion resistance to highly reactive chemicals and gases, coupled with its ability to maintain high purity levels, contributes to the reliability and efficiency of semiconductor fabrication processes. The alloy’s compatibility with semiconductor materials and processes ensures consistent performance in critical manufacturing environments.

Environmental and Waste Treatment

In environmental and waste treatment applications, Hastelloy C-276 addresses the challenges posed by corrosive and toxic substances encountered in water treatment plants, pollution control systems, and waste disposal facilities. The alloy’s resistance to corrosion from acids, oxidizing agents, and organic compounds makes it suitable for components such as pumps, valves, and filtration systems. Hastelloy C-276’s durability and reliability in harsh environmental conditions contribute to the effective management and treatment of industrial waste and pollutants, supporting environmental sustainability efforts.

Research and Development

Hastelloy C-276 plays a vital role in research and development (R&D) laboratories and facilities where corrosion-resistant materials are required for experimental setups, test rigs, and analytical instrumentation. Its versatility and ability to withstand aggressive chemicals, high temperatures, and corrosive atmospheres make it an essential material for conducting scientific research and developing new technologies. Hastelloy C-276’s reliability in maintaining structural integrity and performance under extreme conditions support innovation and advancement across various scientific disciplines.

In conclusion, Hastelloy C-276’s widespread applications across industries such as food and beverage, semiconductor manufacturing, environmental and waste treatment, and research and development highlight its versatility, durability, and reliability as a corrosion-resistant alloy. Its unique properties make it indispensable in critical infrastructure and advanced technology applications, ensuring safety, efficiency, and sustainability in diverse industrial sectors.

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.