Maintenance Tips for Hastelloy C-276: Ensuring Longevity and Performance

Jul 12, 2024

Introduction to Hastelloy C-276 Maintenance

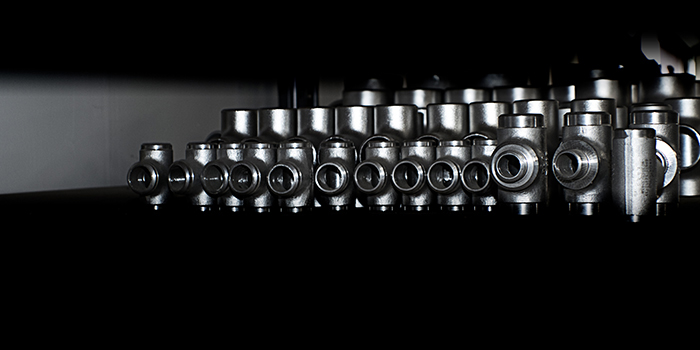

Maintenance is crucial for preserving the exceptional properties of Hastelloy C-276, a highly corrosion-resistant alloy widely used in demanding industrial environments. Regular upkeep not only ensures longevity but also sustains its performance under varying conditions. This blog explores essential maintenance practices tailored to optimize the durability and reliability of Hastelloy C-276 in industrial applications.

Hastelloy C-276, composed primarily of nickel, molybdenum, and chromium, offers superior resistance to corrosion, oxidation, and stress-related cracking. Its robust properties make it indispensable in industries such as chemical processing, oil and gas, aerospace, and more, where exposure to corrosive chemicals, high temperatures, and harsh environments is common.

Regular Inspection Practices

To maintain Hastelloy C-276’s effectiveness, regular inspections are paramount. Scheduled inspections help detect early signs of corrosion, wear, or structural degradation before they compromise performance or safety. Inspections should encompass visual assessments, non-destructive testing methods like ultrasonic testing or dye penetrant inspection, and monitoring of operating conditions such as temperature and pressure.

Establishing routine inspection intervals based on environmental exposure and operational demands is crucial. For instance, components exposed to aggressive chemicals or fluctuating temperatures may require more frequent inspections. Early detection allows for timely corrective actions, minimizing downtime and extending the service life of Hastelloy C-276 equipment.

Cleaning Methods

Proper cleaning practices are essential to maintain Hastelloy C-276’s corrosion resistance and surface integrity. Before cleaning, it’s essential to assess the type of contaminants and the appropriate cleaning agents that won’t compromise the alloy’s properties. Mild detergents or specialized cleaners recommended by the alloy manufacturer are typically suitable.

Mechanical methods such as brushing or scrubbing should be gentle to avoid surface damage. For stubborn deposits or corrosion, techniques like passivation or pickling may be necessary under controlled conditions. Post-cleaning, thorough rinsing and drying are critical to remove residual cleaning agents and prevent contamination.

Adhering to proper cleaning protocols ensures Hastelloy C-276 remains free from contaminants that could accelerate corrosion or compromise performance. Effective cleaning practices are foundational to the overall maintenance strategy, enhancing the alloy’s longevity and maintaining its ability to perform in challenging industrial environments.

Preventive Maintenance Strategies

Implementing preventive maintenance measures is essential to maximize the lifespan of Hastelloy C-276 components. These strategies aim to proactively address potential issues before they escalate, ensuring continuous performance and reliability. One effective approach is to establish regular maintenance schedules based on operating conditions and environmental factors. This includes routine inspections, cleaning, and testing to identify early signs of wear, corrosion, or mechanical stress.

Surface treatments such as coatings or passivation can provide additional protection against corrosive agents, extending the alloy’s resistance to degradation. Applying protective coatings tailored to specific operating environments enhances Hastelloy C-276’s ability to withstand chemical exposure and mechanical wear.

Handling Corrosive Environments

Managing Hastelloy C-276 in highly corrosive environments requires proactive measures to mitigate potential damage and maintain performance. It’s crucial to assess exposure levels to corrosive chemicals, acids, or abrasive substances regularly. Monitoring environmental conditions such as pH levels, temperature variations, and exposure duration helps anticipate potential corrosion risks.

When handling corrosive substances, implementing proper containment measures and ensuring adequate ventilation can minimize direct exposure to Hastelloy C-276 components. Selecting compatible sealing materials and gaskets that complement the alloy’s corrosion resistance further enhances protection against chemical ingress and leakage.

Temperature and Pressure Management

Effective management of temperature and pressure conditions is critical to optimizing Hastelloy C-276’s performance and longevity. The alloy exhibits robust resistance to oxidation and thermal stability, but prolonged exposure to extreme temperatures or rapid temperature fluctuations can impact its mechanical properties.

Monitoring and controlling operating parameters within recommended limits mitigate thermal stress and potential deformation of Hastelloy C-276 components. This includes thermal cycling analysis and stress testing to assess material response under varying temperature and pressure conditions. Implementing thermal barriers or insulation where applicable helps maintain consistent operating temperatures and minimizes thermal shock.

By proactively managing temperature and pressure factors, industries can mitigate risks associated with thermal expansion, contraction, and mechanical fatigue. Hastelloy C-276’s ability to maintain structural integrity under demanding thermal conditions reinforces its reliability in critical industrial applications.

Repair and Replacement Guidelines

Knowing when to repair or replace Hastelloy C-276 components is crucial for maintaining optimal performance and safety. Assessing the extent of damage through thorough inspection and testing helps determine the appropriate course of action. Minor surface corrosion or wear may be addressed through surface treatments or localized repairs, such as welding or re-passivation, conducted by qualified personnel familiar with Hastelloy C-276’s properties.

For more extensive damage affecting structural integrity or critical components, replacement is often recommended to prevent potential failures. Choosing certified replacement parts ensures compatibility and maintains the alloy’s original specifications and performance characteristics. Establishing clear guidelines for repair and replacement based on inspection results and industry standards helps optimize maintenance efforts and minimize downtime.

Storage and Handling Practices

Proper storage and handling practices are essential to prevent contamination and maintain Hastelloy C-276’s corrosion resistance during storage, transport, and installation. Components should be stored in clean, dry environments free from exposure to moisture, corrosive chemicals, or abrasive materials. Utilizing protective covers or packaging that shield against physical damage and environmental pollutants helps preserve surface integrity.

During handling and installation, precautions such as using non-metallic lifting slings or soft fabric wraps minimize contact that could scratch or abrade Hastelloy C-276 surfaces. Avoiding direct contact with incompatible metals or materials that could initiate galvanic corrosion is critical. Implementing handling procedures that prioritize careful manipulation and secure fastening reduces the risk of mechanical stress or deformation.

Environmental Considerations

Environmental factors can impact Hastelloy C-276’s performance and longevity, requiring tailored strategies to mitigate potential risks. Assessing exposure to outdoor elements, airborne pollutants, or chemical spills helps identify preventive measures. Implementing protective coatings or barriers that shield against UV radiation, moisture, or airborne contaminants enhances the alloy’s resistance to environmental degradation.

In facilities where hazardous chemicals or corrosive agents are present, implementing secondary containment measures and emergency response protocols minimizes exposure risks to Hastelloy C-276 components. Regular monitoring of environmental conditions and conducting periodic audits ensure compliance with safety regulations and enhance environmental stewardship practices.

Case Studies and Success Stories

Highlighting real-world applications and success stories illustrates the effectiveness of maintenance practices in optimizing Hastelloy C-276 performance. Case studies showcasing industries that have implemented proactive maintenance strategies and achieved prolonged service life and operational efficiency with Hastelloy C-276 can provide valuable insights and benchmarks for other applications.

By sharing case studies, industries can learn from best practices and innovative approaches to maintaining Hastelloy C-276’s integrity and performance in diverse industrial environments. These examples underscore the alloy’s reliability and versatility in addressing complex challenges while supporting sustainable operations and minimizing lifecycle costs.

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.