The Definitive Guide to Flange Types

Feb 10, 2026

Why Understanding Flange Types is Critical for Industrial System Integrity

Flange types are essential components in any industrial piping system, providing the mechanical connection between pipes, valves, pumps, and other equipment. The right flange ensures a leak-proof seal, allows for easy maintenance, and maintains system integrity under demanding conditions.

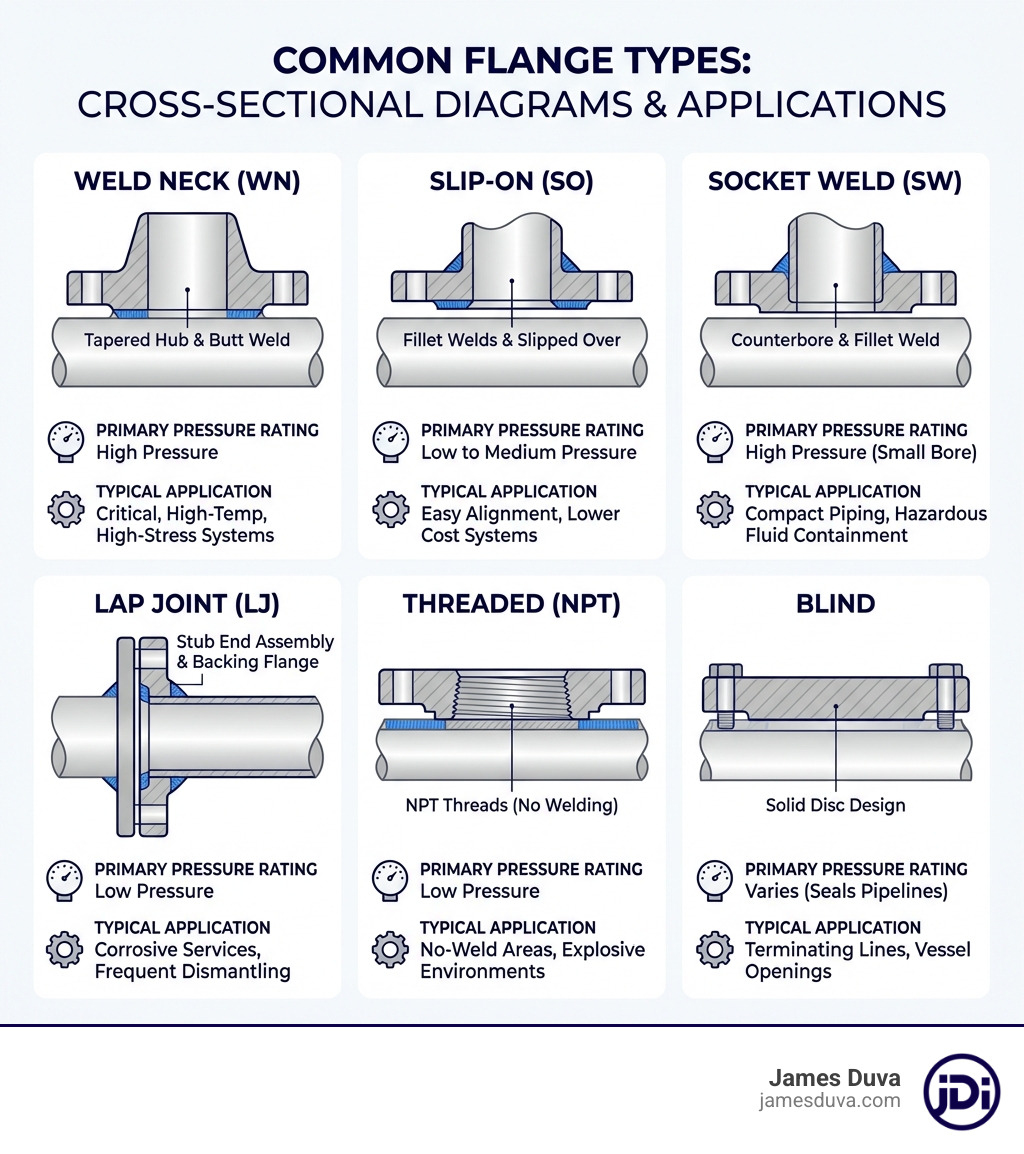

The 6 Most Common Flange Types:

- Weld Neck (WN) – Tapered hub with butt weld; best for high-pressure, high-temperature, and critical applications

- Slip-On (SO) – Lower cost with fillet welds; suitable for low-pressure systems requiring easy alignment

- Socket Weld (SW) – Counterbore design with fillet weld; ideal for small-bore, high-pressure piping

- Lap Joint (LJ) – Two-piece assembly with rotatable backing flange; cost-effective for corrosive services requiring frequent dismantling

- Threaded (Screwed) – No welding required; used in low-pressure systems or explosive environments

- Blind – Solid disc without bore; terminates pipelines or seals vessel openings

In industries like chemical processing and oil & gas, selecting the wrong flange type can lead to catastrophic failures, as there is zero tolerance for leakage. Different flange types offer varying levels of strength, pressure ratings, and cost. A weld neck flange provides maximum integrity for critical, high-pressure applications, while a slip-on flange offers easier installation at a lower cost but has significantly lower strength and fatigue life.

Flanges are critical for:

- Joint integrity – Ensuring leak-proof connections that withstand system pressures and temperatures.

- Maintenance access – Allowing easy disassembly for inspection or modification without cutting pipes.

- System flexibility – Enabling connections between different equipment types and pipe sizes.

- Safety – Preventing hazardous leaks in systems handling flammable, toxic, or corrosive materials.

Material selection is equally important. While carbon steel flanges are common, industries handling corrosive substances often require stainless steel or nickel alloy flanges to resist degradation and maintain long-term system integrity. For a broader technical background on flanges in piping, you can also review the overview of pipe flanges on Wikipedia alongside the in-depth resources from James Duva Inc..

I’m Billy Walker, Vice President at James Duva Inc., where I’ve spent years helping engineers and contractors specify the right flange types for demanding applications in nuclear, chemical processing, and water treatment industries. Understanding the nuances of each flange type is essential for sourcing the right components for your critical systems.

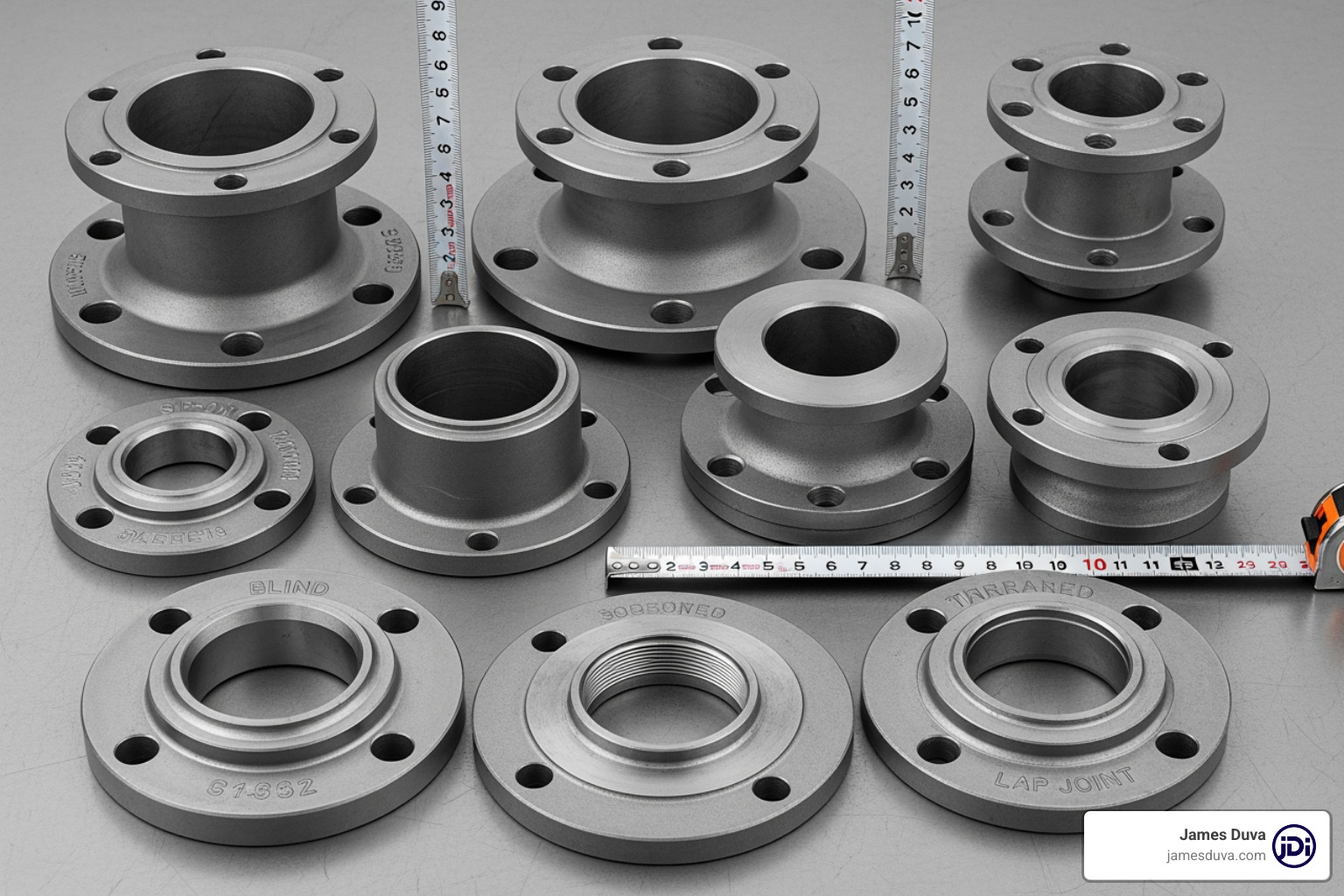

An In-Depth Look at Common Industrial Flange Types

This section explores the most frequently used flange types in industrial piping, detailing their design, installation, and ideal applications. At James Duva Inc., our expertise since 1978 helps us guide clients in Branchburg, NJ, and beyond, to the perfect fit for sectors like chemical processing and oil & gas. You can browse many of these configurations in our industrial flanges product category.

Weld Neck (WN) Flanges

The Weld Neck flange is synonymous with high-integrity connections. Its long, tapered hub transitions to the pipe’s wall thickness, allowing for a full-penetration butt weld that transfers stress from the flange to the pipe, providing excellent reinforcement.

Key characteristics and applications:

- High-integrity joint: The butt weld ensures a strong, leak-proof seal, making it ideal for critical applications like high-pressure oil and gas pipelines.

- Stress distribution: The tapered hub optimizes stress distribution, making Weld Neck flanges well-suited for systems with high pressure, extreme temperatures, or repeated bending.

- Radiographic testing: The butt weld can be easily examined by radiography, allowing for non-destructive testing to verify weld quality, a crucial advantage where failure is not an option.

- Flow efficiency: The flange’s bore matches the pipe’s inside diameter, preventing flow restriction, minimizing turbulence, and reducing erosion.

Weld Neck flanges are primarily used in larger diameters and higher-pressure classifications, where their superior strength justifies their higher cost and more complex installation. For more insights, explore our article on Understanding Industrial Flanges: Types, Applications, and Benefits, or review our current range of high-pressure flanges suitable for demanding services.

Slip-On (SO) Flanges

Slip-On flanges are a popular, cost-effective choice known for easy installation. They slip over the pipe’s outside diameter and are secured with two fillet welds—one outside and one inside.

Key characteristics and applications:

- Easier alignment and lower cost: Their simple installation, which permits pipe length adjustment, makes assembly quicker and lowers initial costs compared to Weld Neck flanges.

- Fillet welds: The flange is connected with two fillet welds, which is a simpler process than a butt weld but results in lower overall strength.

- Lower strength and fatigue life: A Slip-On flange has about two-thirds the strength and one-third the fatigue life of a Weld Neck. We recommend them for low to moderate pressure applications.

- When to use with caution: We advise against using Slip-On flanges in systems with extreme temperature and pressure cycles. For services involving severe erosion, crevice corrosion, or cyclic loading, double-welding is recommended.

Socket Weld (SW) Flanges

Socket Weld flanges are used for small-bore, high-pressure piping. The pipe is inserted into a counterbore (socket) and secured with a single fillet weld on the hub.

Key characteristics and applications:

- Good static strength and fatigue life: Socket Weld flanges have about 50% greater fatigue resistance than double-welded Slip-On flanges.

- Ideal for small-bore, high-pressure piping: They are typically used in nominal pipe sizes up to NPS 4 for high-pressure and high-temperature services.

- 1.6mm expansion gap: A critical installation detail is leaving a 1/16 inch (1.6 mm) gap between the pipe end and the socket shoulder before welding. This prevents cracking from thermal expansion.

- Potential for crevice corrosion: The gap can be a site for crevice corrosion, especially in stainless steel systems. For this reason, they should be avoided in services where crevice corrosion or severe erosion may occur, as specified by codes like ASME B31.3.

Lap Joint (LJ) Flanges

Lap Joint flanges are a unique two-piece assembly ideal for systems needing frequent disassembly or handling corrosive fluids. They are not welded directly to the pipe.

Key characteristics and applications:

- Two-piece assembly with Stub End: A Lap Joint flange is used with a “Stub End,” which is butt-welded to the pipe. The flange then slips loosely over the Stub End.

- Rotatable backing flange: The flange’s ability to rotate simplifies bolt hole alignment, saving time and effort during assembly.

- Cost-effective for exotic materials: For systems requiring expensive corrosion-resistant materials (like stainless steel or nickel alloys), only the Stub End needs to be made from the costly alloy. The backing flange can be made from cheaper carbon steel, reducing overall costs.

- Lower pressure-holding capacity: Lap Joint assemblies have a lower fatigue life than Weld Neck flanges (about one-tenth) and are generally used in low-pressure, non-critical applications.

For a broader understanding of various flange types, you can visit our comprehensive resource on Flanges and explore compatible stub ends and fittings for complete assemblies.

Threaded (Screwed) Flanges

Threaded (or screwed) flanges can be attached to a pipe without welding, making them ideal where welding is hazardous or impractical, such as in explosive environments.

Key characteristics and applications:

- No welding required: The pipe is screwed into the flange using NPT threads, eliminating the need for hot work and reducing installation complexity.

- Used in low-pressure systems: They are predominantly found in low-pressure, low-temperature connections like water and air utilities.

- Not for thin-walled pipe: Threading reduces a pipe’s wall thickness, so threaded flanges require thicker pipes (Schedule 80 or heavier) to maintain integrity.

- Reusability: If undamaged, threaded flanges can often be salvaged and reused, offering potential cost savings.

Blind Flanges

Blind flanges are solid discs with no bore. Their function is to terminate a pipeline or seal a pressure vessel opening.

Key characteristics and applications:

- Terminate or seal: They are used to close off the end of a flanged pipeline, valve, or vessel opening.

- Manhole covers: On pressure vessels, they can serve as manhole covers for inspection or maintenance access.

- High stress resistance: Blind flanges are among the most highly stressed flange types and must resist significant pressure from system fluid and bolting forces.

- Easy access for maintenance: Their bolt-on nature makes them ideal for creating access points for maintenance, repair, or pressure testing.

For more in-depth information on this component, see our article on Slip Blind Flanges: What They Are and Why They Matter and explore our stocked range of blind and slip blind flanges.

Comparing Key Flange Types: Installation, Strength, and Cost

Understanding the nuances of each flange type is crucial, but seeing them side-by-side can truly highlight their differences. We’ve compiled a comparison of the most common flange types based on critical engineering criteria. When you are ready to specify components, you can match these characteristics with items available in our flanges catalog.

| Feature | Weld Neck (WN) Flange | Slip-On (SO) Flange | Socket Weld (SW) Flange | Lap Joint (LJ) Flange |

|---|---|---|---|---|

| Installation Method | Butt welded to pipe; single, full-penetration weld. | Slips over pipe, secured by two fillet welds (inside/outside). | Pipe inserted into counterbore, secured by one fillet weld (outside). | Used with Stub End, which is butt welded to pipe; flange slips loosely over stub end. |

| Relative Strength | Highest (100%) | Moderate (approx. 2/3 of WN) | Good (50% greater fatigue strength than double-welded SO) | Low (approx. 1/10 of WN) |

| Pressure/Temp Rating | Highest (suitable for all pressure classes, high temp) | Low to Moderate (typically Class 150-600, not for extreme) | Moderate to High (typically for small bore, high pressure) | Low (typically Class 150-300, non-critical) |

| Fatigue Life | Highest (100%) | Lowest (approx. 1/3 of WN) | Good (better than SO) | Very Low (approx. 1/10 of WN) |

| Relative Cost | Highest (due to material & welding complexity) | Moderate (lower initial cost, easier alignment) | Moderate (similar to SO) | Moderate (flange can be cheaper material, stub end costly) |

| Typical Applications | Critical, high-pressure, high-temperature, severe cyclic service, oil & gas, chemical processing. | Low-pressure, low-temperature, general service, fire protection, HVAC. | Small-bore, high-pressure, non-corrosive, non-critical, utility lines. | Frequent dismantling, corrosive service (with expensive stub end), alignment issues. |

For help turning this comparison into a finalized bill of materials, our team at James Duva Inc. can assist with selecting compatible fittings and pipes to complete your system.

How to Select the Right Flange for Your Application

Choosing the correct flange is crucial for system safety, reliability, and longevity. This section covers the engineering considerations that guide the selection process, ensuring that the components sourced from James Duva Inc. are perfectly matched to your project’s demands.

Critical Factors Influencing Flange Selection

Selecting the right flange requires a holistic approach, considering the specific operating conditions to ensure reliability and safety. Key factors include:

- Pressure-temperature rating: Every flange has a pressure-temperature rating (or Class) that must match the system’s operating conditions. An ASME Class 150 flange has a very different pressure capability than a Class 600.

- Fluid properties: The nature of the fluid—whether it is corrosive, erosive, flammable, or toxic—directly dictates the material choice and sometimes the flange type.

- Corrosion resistance: If the fluid or environment is corrosive, materials like 316L stainless steel or higher premium stainless steel materials are needed to prevent degradation. Crevice corrosion is a specific concern with Socket Weld flanges.

- Erosion resistance: High-velocity or abrasive fluids require flange types with smooth bores (like Weld Necks) and wear-resistant materials.

- Maintenance requirements: Systems needing frequent access benefit from Lap Joint or Blind flanges for their ease of disassembly.

- Material selection: Material choice depends on mechanical properties, temperature limits, and weld compatibility. James Duva Inc. excels in providing flanges in high-grade stainless steel and nickel alloys for demanding applications, which you can explore in our flanges product listings.

- Cost considerations: Initial cost must be weighed against long-term reliability, safety, and maintenance expenses. A cheaper flange that fails is never a true cost-saving.

For complex projects, reviewing our broader inventory of pipes and fittings alongside flange options can help you design a fully compatible system.

A Guide to Flange Facing Flange Types

The flange facing is the gasket-contact surface, and its design is critical for a leak-proof seal. Different flange types offer various facing styles for specific conditions.

- Raised Face (RF): The most common type, with a gasket surface raised above the bolting circle. This concentrates pressure on the gasket for a better seal. The raised height is typically 1/16 inch for flanges under Class 400 and 1/4 inch for Class 400 and higher.

- Flat Face (FF): The gasket surface is on the same plane as the bolting circle. FF flanges are used with cast iron equipment that could break under the concentrated load of an RF flange.

- Ring Type Joint (RTJ): Designed for high-pressure, high-temperature applications, RTJ facings have a groove that holds a metallic ring gasket, creating a robust metal-to-metal seal.

- Tongue and Groove (T&G): These matching faces self-align and create a strong seal, often used in valve bonnets and pump covers.

Sealing and Gasket Selection: The facing type determines the gasket. RF and FF flanges use non-metallic or spiral-wound gaskets, while RTJ flanges require specific metallic ring gaskets. Our team can help you select the right gasket for optimal performance and pair it with compatible ASME B16.5 flanges.

Surface Finish (AARH): The facing’s surface roughness, measured as Arithmetical Average Roughness Height (AARH), is critical. ASME B16.5 specifies finishes between 125 to 500 AARH, which is essential for an effective seal.

Understanding International Standards for Flange Types

Standardization ensures interchangeability, safety, and reliability. For flange types, several international standards govern their design and dimensions.

-

ASME/ANSI standards (USA): In the U.S., ASME and ANSI standards are the benchmark.

- ASME B16.5 for flanges up to 24″: This is the most common standard, covering pipe flanges from NPS 1/2 to NPS 24. It defines pressure-temperature ratings, materials, dimensions, and tolerances. You can reference the official standard at ASME B16.5 for flanges up to 24″ while comparing to the ASME-class flanges stocked by James Duva Inc..

- ASME B16.47 for large diameter flanges: This standard covers larger flanges from NPS 26 to NPS 60, defining two non-interchangeable series: Series A and Series B. More detail is available in ASME B16.47 for large diameter flanges.

- Pressure Classes: ASME standards group flanges into pressure classes (e.g., Class 150, 300, 600, 900, 1500, 2500), which indicate the maximum allowable working pressure at specific temperatures.

-

DIN/EN standards (European): In Europe, DIN EN 1092-1 is the primary standard, using PN (Nominal Pressure) ratings like PN10 and PN16.

-

Interchangeability issues: It is critical to know that flanges from different standards (e.g., ASME vs. EN) are not interchangeable. Even within ASME, a Class 150 flange will not mate with a Class 300 flange. We ensure compliance with the specific standards required for your project and can help you consolidate around a consistent standard across your piping components.

Frequently Asked Questions about Flanges

We often receive questions from engineers and procurement specialists about the best flange types for their projects. Here are some of the most common inquiries, clarified by our experts at James Duva Inc.

What is the strongest type of flange?

Weld Neck flanges are the strongest type. Their tapered hub and full-penetration butt weld provide superior stress distribution and joint integrity. This design, which can be radiographically inspected, is ideal for high-pressure, high-temperature, and severe cyclic services where reliability is critical.

Can you use a Slip-On flange for high-pressure applications?

Slip-On flanges are not recommended for high-pressure or critical applications. Their fillet weld connection offers only about two-thirds the strength and one-third the fatigue life of a Weld Neck flange. They are best suited for low-to-moderate pressure systems where cost and ease of installation are prioritized over maximum strength.

What is the main advantage of a Lap Joint flange?

The main advantage of a Lap Joint flange is cost-effectiveness in corrosive systems. Only the Stub End, which contacts the fluid, needs to be made of an expensive, corrosion-resistant material like stainless steel; the backing flange can be made from cheaper carbon steel. A second advantage is that the rotating backing flange simplifies bolt alignment, saving labor, especially in systems requiring frequent dismantling for maintenance. To see how Lap Joints integrate with corrosion-resistant materials, review our article on premium stainless steel materials and our current flange offerings.

Conclusion: Ensuring System Integrity with the Right Flange Supplier

Selecting the correct flange type is a foundational step in designing a safe and efficient industrial piping system. From the high integrity of Weld Neck flanges to the flexibility of Lap Joints, each type serves a specific purpose. Understanding the nuances of installation, strength, pressure ratings, and material compatibility is not just good practice—it’s essential for operational safety and longevity.

For critical applications in industries like chemical processing and oil & gas, partnering with an experienced supplier is key. At James Duva Inc., based in Branchburg, NJ, we have provided high-grade stainless steel and nickel alloy flanges and fittings since 1978, ensuring you get the right components for your project. Our expertise in these materials and various flange types allows us to guide you to solutions that meet the most demanding specifications.

We pride ourselves on being a trusted one-stop shop, offering not just products but also the knowledge to help you make informed decisions. When system integrity is on the line, let our experience work for you. Explore our extensive inventory of industrial flanges and complementary pipes and fittings to build a complete, code-compliant system for your next project.

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.