Understanding Duplex 2205: Properties, Advantages, and Applications

Aug 7, 2024

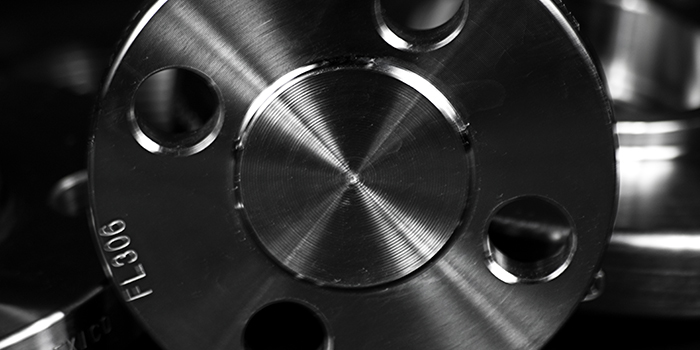

Duplex 2205, a high-performance stainless steel alloy, is widely recognized for its exceptional combination of strength and corrosion resistance. This versatile material finds application across various industries due to its remarkable properties and advantages. This article provides a thorough understanding of Duplex 2205, covering its chemical composition, mechanical properties, corrosion resistance, advantages, applications, and maintenance practices.

Introduction to Duplex 2205

Duplex 2205 is a type of stainless steel that belongs to the duplex family of alloys, characterized by a unique microstructure composed of both austenitic and ferritic phases. This dual-phase structure imparts a combination of properties that make Duplex 2205 an ideal choice for demanding industrial applications. The alloy’s composition, which typically includes chromium, nickel, molybdenum, and nitrogen, contributes to its enhanced performance in various environments.

Chemical Composition and Microstructure

The chemical composition of Duplex 2205 plays a crucial role in defining its properties. The alloy generally contains approximately 22% chromium, 5% nickel, 3% molybdenum, and small amounts of nitrogen, manganese, and silicon. This specific blend of elements results in a microstructure with a balanced mix of ferrite and austenite, providing superior strength and resistance to corrosion.

The ferritic phase of Duplex 2205 contributes to its high tensile strength and resistance to stress corrosion cracking, while the austenitic phase enhances toughness and ductility. This combination of phases creates a material that is both strong and resistant to deformation, making it suitable for a range of challenging applications.

Mechanical Properties

Duplex 2205 is renowned for its exceptional mechanical properties, which include high tensile strength, yield strength, and toughness. Compared to conventional austenitic stainless steels like 304 and 316, Duplex 2205 offers approximately double the yield strength, making it a preferred choice for applications that require high load-bearing capacity.

The alloy’s tensile strength typically ranges between 700 to 800 MPa, while its yield strength can exceed 550 MPa. Additionally, Duplex 2205 exhibits good impact toughness even at low temperatures, making it suitable for use in environments where mechanical stress and temperature fluctuations are a concern.

Corrosion Resistance

One of the most significant advantages of Duplex 2205 is its superior corrosion resistance. The alloy’s high chromium and molybdenum content enhances its resistance to pitting and crevice corrosion, particularly in chloride-rich environments. This makes Duplex 2205 an excellent choice for applications in the chemical processing, oil and gas, and marine industries.

Duplex 2205 also demonstrates impressive resistance to stress corrosion cracking, a common issue in austenitic stainless steels. The alloy’s dual-phase microstructure helps mitigate the risk of cracking under tensile stress, ensuring long-term performance and reliability in harsh conditions.

Advantages of Duplex 2205

Duplex 2205 offers several advantages over other stainless steels, making it a popular choice for various industrial applications. One of the primary benefits is its cost-effectiveness. Despite its superior properties, Duplex 2205 is often less expensive than high-nickel alloys due to its lower nickel content. This makes it an attractive option for projects with budget constraints.

Another advantage is the alloy’s high strength-to-weight ratio. The increased strength allows for the use of thinner materials, reducing the overall weight of structures and components without compromising performance. This feature is particularly beneficial in industries where weight reduction is crucial, such as aerospace and automotive.

Common Applications

Duplex 2205’s unique properties make it suitable for a wide range of applications. In the oil and gas industry, it is used for equipment exposed to harsh environments, including offshore platforms, pipelines, and pressure vessels. The alloy’s resistance to chloride-induced stress corrosion makes it ideal for these demanding conditions.

In the chemical processing sector, Duplex 2205 is employed for components such as heat exchangers, reactors, and storage tanks. Its resistance to chemical attack and high temperatures ensures reliable performance in processing environments.

The marine industry also benefits from Duplex 2205’s corrosion resistance, with applications including marine structures, desalination plants, and underwater equipment. The alloy’s ability to withstand seawater exposure and resist biofouling contributes to its effectiveness in these environments.

Welding and Fabrication

Welding Duplex 2205 requires careful consideration to maintain its desirable properties. The alloy’s dual-phase microstructure can be sensitive to heat input, which may lead to the formation of undesirable phases or reduced mechanical properties if not managed properly.

When welding Duplex 2205, it is important to use appropriate filler materials and follow recommended procedures to avoid issues such as excessive ferrite or grain growth. Techniques like duplex-specific welding rods and controlled heat input are essential for achieving optimal results.

Fabrication of Duplex 2205 involves processes such as cutting, forming, and machining. The alloy’s higher strength can make machining more challenging compared to austenitic steels, requiring the use of high-quality tools and techniques. However, with proper equipment and practices, Duplex 2205 can be successfully fabricated into various components and structures.

Maintenance and Care

Maintaining Duplex 2205 involves routine inspection and cleaning to ensure its continued performance and longevity. Regular visual inspections can help identify signs of corrosion, wear, or damage, allowing for timely corrective actions.

Cleaning Duplex 2205 should be done with care to avoid using harsh chemicals or abrasive methods that could damage the alloy’s surface. Mild detergents and soft cloths or brushes are typically recommended for routine cleaning. In environments where heavy fouling or contamination occurs, more specialized cleaning methods may be required.

Case Studies and Success Stories

Several industries have successfully utilized Duplex 2205 for their critical applications. For instance, a major oil and gas company employed Duplex 2205 for offshore platform components, benefiting from its resistance to seawater corrosion and high mechanical strength. The alloy’s performance led to reduced maintenance costs and extended service life for the equipment.

In another case, a chemical processing plant used Duplex 2205 for heat exchangers and reactors, achieving improved resistance to chemical attacks and operational efficiency. The alloy’s durability and cost-effectiveness contributed to significant operational savings and enhanced process reliability.

Conclusion and Key Takeaways

Duplex 2205 stands out as a high-performance stainless steel alloy that combines strength, corrosion resistance, and cost-effectiveness. Its unique chemical composition and microstructure make it suitable for a wide range of demanding applications in industries such as oil and gas, chemical processing, and marine.

Understanding the properties, advantages, and applications of Duplex 2205 helps industries make informed decisions when selecting materials for their projects. By adhering to proper maintenance practices and leveraging the alloy’s strengths, organizations can ensure optimal performance and longevity for their Duplex 2205 components and structures.

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.